Over the last two years, North American solar contractors have transformed the residential solar industry into the residential solar-plus-storage industry. This was done by adopting the many types of residential batteries that are commercially available, and successfully delivering a higher-value add to solar property owners.

Unreliable electric grids and ongoing threats of natural disasters will continue to drive the solar+storage industry and, now more than ever, solar contractors need to be well informed about the battery products they adopt in their solar business. To provide additional clarity about the internal operations of these products, we're getting an inside look from the experts at LG Chem into the chemistry within different solar battery solutions!

Lithium Batteries

So, has anyone ever bought a car or cell phone based on the battery type? Probably not, so why are we the contractor being asked about LFP or NMC lithium battery types? Does the common consumer know what battery chemistry is in their cell phones? In their laptops? In their Bluetooth earbuds? I don’t think so. So why are we so interested in lithium chemistries today? Simple, because now we can power our homes with batteries charged by the sun.

First, some basics. A lithium battery is an electrochemical energy storage device, composed of multiple power-producing units called ‘cells’. A cell is then composed of four main parts: a cathode, an anode, a separator, and an electrolyte. A slurry of lithium compounds are coated on the cathode and a charcoal-based coating on the anode; two common cathode recipes being NMC (Nickle Manganese Cobalt) and LFP (Lithium Iron Phosphate) chemistries. Both NMC and LFP are commercially available and being used in a wide range of battery applications from electric vehicles (EVs) to consumer electronic devices. For stationary storage, like home batteries, NMC is the leading chemistry of choice for reasons such as higher-performing cells and increased energy density.

Facts About Lithium Batteries

All lithium batteries, regardless of chemistry or cell type, have the potential to catch fire and experience thermal runaway events. They are potentially dangerous and should be treated as such. Risks can be greatly mitigated by design details, a robust QA/QC process, and monitoring. Mistakenly, LFP batteries have been touted to be inherently safe which is simply not correct. That being said, the National Oceanic and Atmospheric Administration says that your chance of being struck by lightning in the course of a lifetime is about 1 in 13,000. Lithium batteries have a failure rate that is less than one in a million. The failure rate of a quality lithium cell is better than 1 in 10 million.

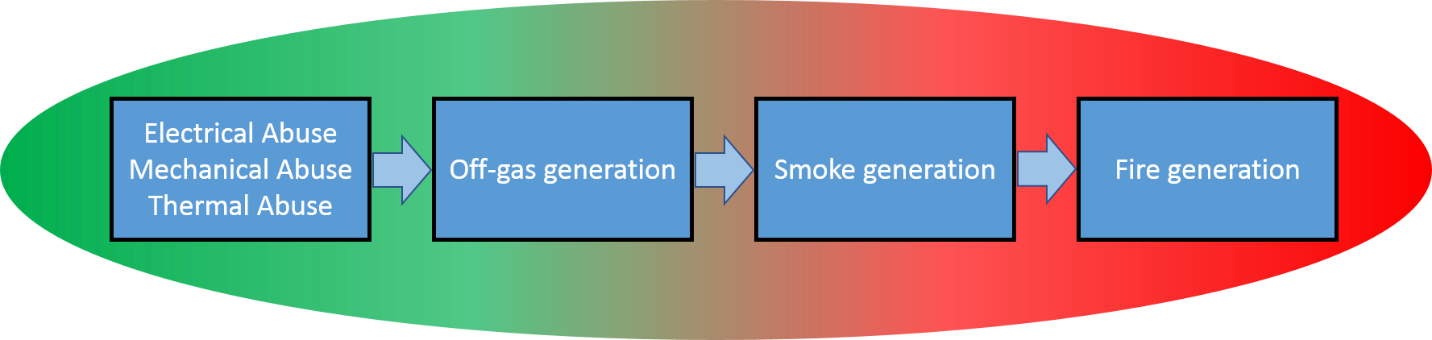

Additionally, cell failure occurs when there’s any or all of (1) electrical abuse (2) mechanical abuse and/or (3) thermal abuse. This will cause the cell to off-gas which will smoke and eventually combust. All lithium-ion cells will generate potentially combustible gases when overheated. If combustion occurs, there is a risk for a neighboring cell to ignite, and then the next neighboring cell and so forth. This is called thermal runaway and any lithium chemistry can reach this stage.

The reality is that we use lithium batteries in our everyday lives, all shapes and sizes, and battery cell failures can occur on an extremely rare basis. Regardless of chemistry, lithium battery safety should be taken seriously, especially for larger lithium batteries. Industry practice, at a minimum, is to adhere to global and national safety certifications based on multiple rigorous battery testing procedures. Only certified lithium batteries should be used, by trained professionals, and they should be used for their intended application only. Any battery used outside of the intended application could have negative repercussions.

As it relates to home battery products, NMC cells are used in the vast majority of passenger cars made by the world’s leading automotive OEMs because of NMC’s superior energy density (approx. double LFP’s energy density). Automotive OEMs are extremely risk-averse and their technical and commercial teams have completed exhaustive due diligence comparing chemistries and vendors’ manufacturing facilities. Having a residential battery comprising cells that have passed such demanding examination and testing should deliver a high level of confidence.

In the end, how do you choose between LFP and NMC? Well, how do you know which chemistry is in your phone? Your laptop? The answer is we don’t know, because we don’t buy things based on the battery type. What we do know is from the data, available today, demonstrating the safety and performance track record of quality lithium cells being used for a wide range of applications. When it comes to safety, our chances have been and will continue to be pretty good.

Additional Resource's:

https://batteryuniversity.com/learn/article/types_of_lithium_ion

Comments

I came here looking for information about a specific battery chemistry because I know the different failure modes and want to know whether this particular battery is suitable for my application. Imagine my disappointment when what I find is a sales job denigrating the customer’s questions about battery chemistry.

I agree 100% with the comment above by Michael. My phone and laptop live in an entirely different temperature and physical environment from an my EV. My EV will have to live through the worst of the climate found in the Sonoran Desert, and I believe the differences between the two chemistries in an EV may be significant. I'm not going to buy an EV until I know what chemistry it comes with and all of the sensitivities that it has in the climate it will be operated in.