In August of 2010, I learned of a friend and neighbor who had been the first to get in on a new Feed in Tariff (FIT) program offered through our local power company. The open enrollment was on a first-come, first-serve basis and filled up in just a few minutes on their opening day July 1, at the going rate of $.65 kWh for 15 years. Their next enrollment date would be on October 1 at a reduced rate (~10% less) and this pattern would continue a couple of times per year until they filled their quota. I had been interested in wind, solar, and even micro hydro for some time as possible alternative energy sources at my home location. While conditions at my site qualified for our state's wind energy program, zoning, and program obstacles prevented me from going that route.

In September, I got several quotes from local installers for systems in the 9 kW size range as 10 kW was the maximum size allowed in our program and since they allowed a 10% variance, it gave me the greatest flexibility. While I couldn't afford any of the quotes I received, I was still interested in learning more and was hoping to find a more DIY route. On Oct. 1, at 8:00 am sharp, I decided to gamble on the enrollment fee of $180 and logged on and completed my application in the few minutes before it filled up. I would have until Oct. 15, 2011, to have my system installed and pass local inspection. In the meantime, I would work through the permitting steps, try to find an approved "solar installer" that would work with me, and hope equipment prices would fall.

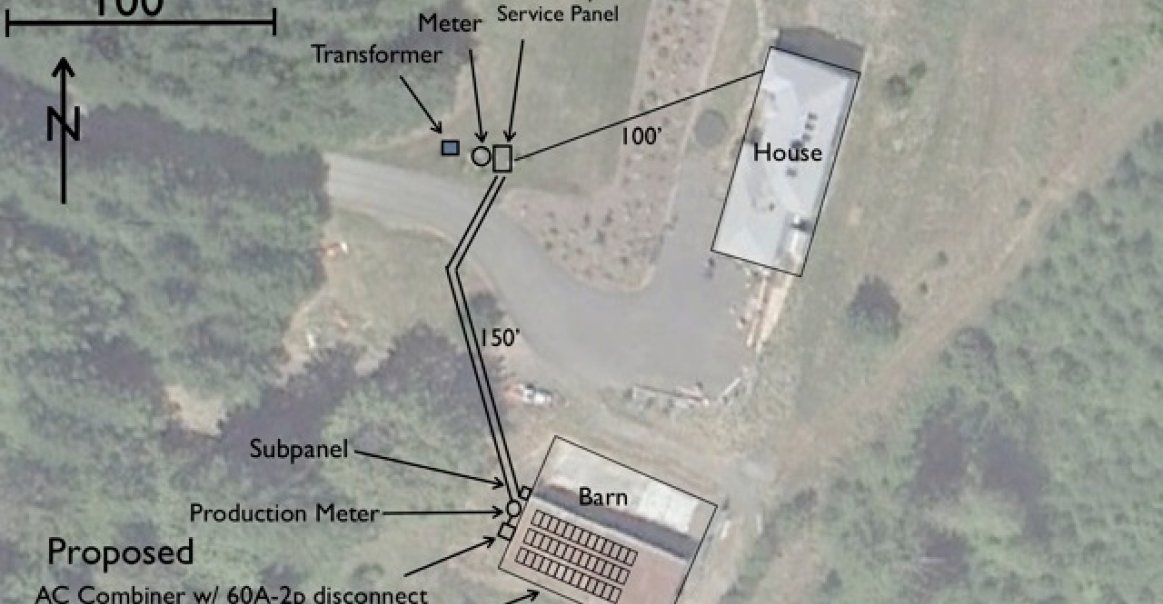

My setup was a bit unusual as my meter main was 100' from my house which did not have much roof with southern exposure. My barn, 150' from the meter main, had plenty of south-facing roofs and would help supply the electrical needs for our small farm operations. In addition to a lot of work in getting power to and from the barn, I needed to strengthen the barn and add rail attachment points. In the process, I changed my roof to white for greater reflectivity and cooler operating temperatures. In all, more work to make the barn "solar worthy" than actually installing the PV system. To learn about Solar PV, I purchased "Photovoltaic Systems" by J. Dunlop and used the internet extensively. Many of the vendor's tools were extremely helpful in designing and clarifying the installation process. Even with such rapid growth, the industry is impressive and the many folks I spoke with were extremely helpful.

The most challenging parts of this project were the red tape and permit requirements along with the stress of unknowns you were afraid to ask about in case it opened another can of worms. While my state is a strong promoter of alternative energy, the regulatory hurdles for small residential PV solar systems can be extensive and add significantly to the cost and time of installation. As an example, my friend had to pay $800 for a wildlife impact study for putting solar panels on his roof. All of his neighbors interested in PV would have had this same requirement as well. Our state code also doesn't allow panels to be tilted more than 18" off the slope of the roof, which amounts to a 5% difference in production in my case. Like promoting fuel-efficient vehicles but then forcing them to run on deflated tires because they want a lower profile. A low profile on a historic building is understandable, but statewide, that is ludicrous! These kinds of impediments and restrictions, of which there are many, will keep Solar PV from wider adoption, especially for folks wanting to start small as it significantly increases the price per watt. As prices of equipment continue to drop, the permitting fees and labor to go through these processes make up an increasing percentage of the cost of a PV system installation.

By September 2011, I had my permit in hand and was seeing more than a $1./ watt drop in PV modules since the previous December. I had shopped around a lot and the help I received at Greentech Renewables was excellent and they were very competitive on the American-made panels I wanted. From the DIY perspective, it was great having someone like Ryan who could answer my questions but was honest enough to tell me when he didn't know and track down the answers. He also made sure I had all the right size parts and connectors (details a first-timer often overlooks), which was critical since my timeline was so short. Everything was in stock as promised and arrived 5 days after ordering.

It is helpful to remind your vendor what kind of incentive program you may be on. As an example, my barn roof had a relatively low angle of 13 degrees. Using our local rates, PVWatts calculated a $26/year difference if my panels were raised 11 degrees. This would not justify the extra expense, but with the FIT plan, each kWh was 5x more valuable and PVWatts calculated an increase of $120 /year in value if I installed 7" standoffs. For similar reasons, plus the ease of installation, I chose to go with Enphase 215 microinverters to optimize my system's production. Admittedly, I also liked the idea of being able to see each panel's production and figured that if in the future a panel gets damaged, I won't be struggling to find a matching panel or have an entire string's production reduced until I do. With the FIT program I can't use the state's tax credit and subsidy, my only means of paying off the system is with production. Between my standoffs and spacing between rows, installation, maintenance, and or replacing any components is easy. While the folks at Enphase had warned me that my inverters might have trouble communicating over the 250' to the Envoy receiver back at my house, they did have a solution for me. But when I plugged it in, every inverter checked in fine and I have had no problems to date.

On October 6, I passed my final inspection and was ready for the power company to install their two meters. One to record PV production and one to replace my main meter that records both net usage and power sent to the grid. The equation (PV produced + Net Usage - kWh Sent to Grid) = my total usage and is used by the power company to reduce the monthly bill and pay for production. In the few weeks I have had the system running, daily output has ranged between 4 and 43 kWh and so far produced about 4% above PVWatts' estimate. As so many have noted, there is nothing quite like seeing your electric meter run backward! Like pulling into a gas station, off-loading "extra" fuel in the tank, getting paid for it, and driving off. It feels really good. I think it's the ultimate in "buying local", taking advantage of the strength of distributive processing, empowering each of us as producers, at the same increasing our energy awareness, and constantly challenging us to use as little as we produce. Today, my first check from the power company arrived, it feels pretty good. The Oct. 1, 2011, FIT plan opened at $0.37/kWh, and rather than filling up in a few minutes, it is still open.

Portland, OR 97035

United States