Between June 1st and November 30, the East Coast of the United States and the Caribbean are at a higher risk of hurricanes making landfall. These hurricanes -- including Florence, Harvey, Irma, and Maria -- put solar PV under extreme environmental stresses. Until this summer, damages to solar PV arrays as a result of hurricanes would be individually documented in silos, making research on industry-wide best practices challenging to discern. In hopes of tackling this conundrum head-on, researchers Christopher Burgess and Joseph Goodman published “Solar Under Storm” with the Rocky Mountain Institute in June to explicate the best practices for resilient ground-mount PV systems with hurricane exposure.

This article summarizes their key findings and promotes discussion about building rugged, long-lasting PV systems. More solar will be installed in hurricane-prone regions and the storms themselves are intensifying. The RMI's findings remind us of how to ensure the longevity of solar assets.

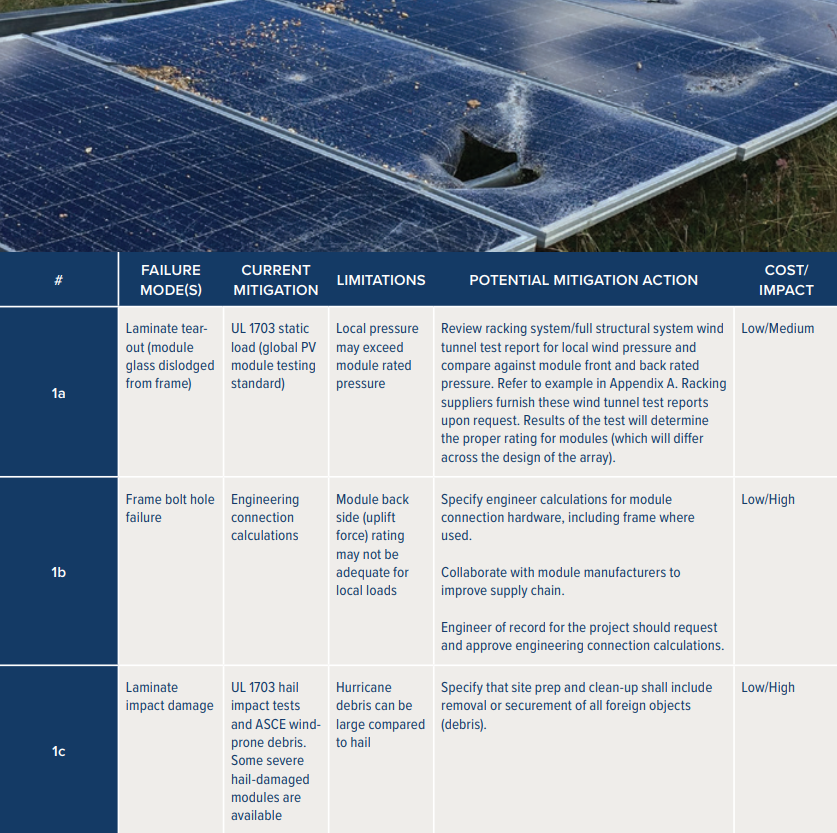

The importance of solar energy in the Caribbean has grown over the past two decades. In fact, over half of the existing Caribbean utilities own or operate PV as part of their generation mix. This proliferation provides ample case studies solar PV’s durability. Despite wind speeds over 180 mph last, a vast majority of PV systems survived the onslaught. In general, solar is known as a resilient energy technology. A report from the National Renewable Energy Laboratory (NREL) on 50,000 solar energy systems installed between 2009 and 2013 indicates that only 0.1% of all PV systems have been reported as affected by damaged or underperforming modules each year some did not. For those systems that did break in the hurricane, the most common points of failure were:

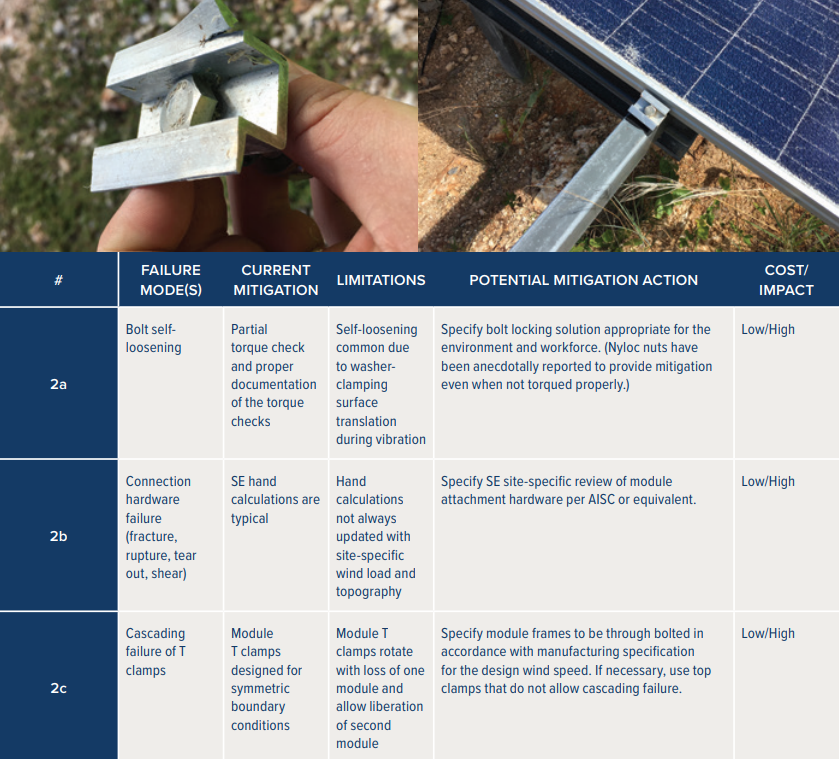

-

Undersized racking

-

Mid-Clamp failure

-

Undersized bolts

-

Under-torqued bolts

-

Lack of lateral racking support

-

Lack of vibration-resistant connections

-

Use of self-tapping screws instead of through bolting

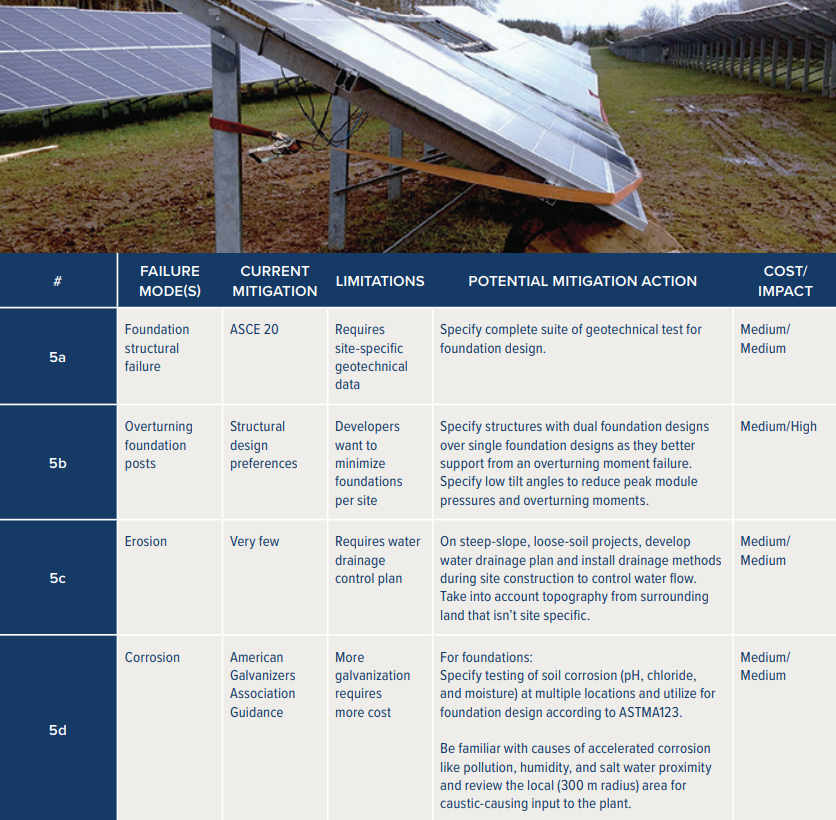

Based on these failure points, RMI makes a number of recommendations. The following suggestions should be incorporated for all ground-mounted arrays in hurricane-prone regions:

-

Require engineering for ASCE 7 site conditions.

-

Specify high-load (112 lb/ft2 Pa uplift) based on structural calculations (many Tier 1 manufacturers currently offer a solution)

-

Require structural engineer review of lateral loads due to racking and electrical hardware (e.g. combiner boxes on an array post causes increased loading)

-

Confirm with racking manufacturers that actual site conditions comply with their base assumptions from wind-tunnel testing.

-

Specify the quality assurance process. Inadequate torquing of bolts is a workmanship issue.

-

Specify bolt hardware locking solution.

PV Module Frame & Laminate

PV Module Connection Hardware

Structural Racking

When it comes to roof-mounted arrays, the same level of diligence must be implemented into design and construction to reduce the risk of falling modules. In 2019, Hurricane Maria ripped through St. Croix and affected a Greentech Renewables commercial storage project at a cinema. To no fault of the attachment and racking manufacturers, the modules simply could not withstand 200 mph wind bursts. Consequently, some bowed under the pressure and released from their clamps. Because the system was constructed with energy storage on-site, the property owners were still able to save money on propane costs by charging and discharging the 400kWh battery system. The panels have since been replaced and the system is fully operational.

It’s important to remember that the vast majority of PV systems endure harsh storms. This is partially what makes them such a compelling energy technology. Nevertheless, in order for damage rates to decline, three market sectors must be considered: research, manufacturing, and installation best practices. While groups like International PV Quality Assurance Task Force and the Durable Module Materials Consortium are channeling recommendations to module manufacturers, it's on the rest of the industry to ensure installations adhere to hurricane-proof standards.