When it comes to designing a PV system for any residential or even commercial system, the 120% rule is used to determine the limit to how much a building or structure can hold or how much energy the site’s service can handle. Yes, maybe the roof, ground or carport can support several kilowatts of PV, but can the service to the site handle it all? This is where you will hear whispers of the 120% rule. Well, what does that even mean?

This rule is meant to calculate how many amps can be backfed through the load side of the site’s existing service equipment with a measure of safety. In this instance, you have to consider that not only is the solar PV system of a certain amperage but also that the grid is present too and it is not sitting idle. With the two sources there to supply the loads with the energy they need, a system that squeaks by without consideration for the 120% rule is a time bomb just waiting to explode.

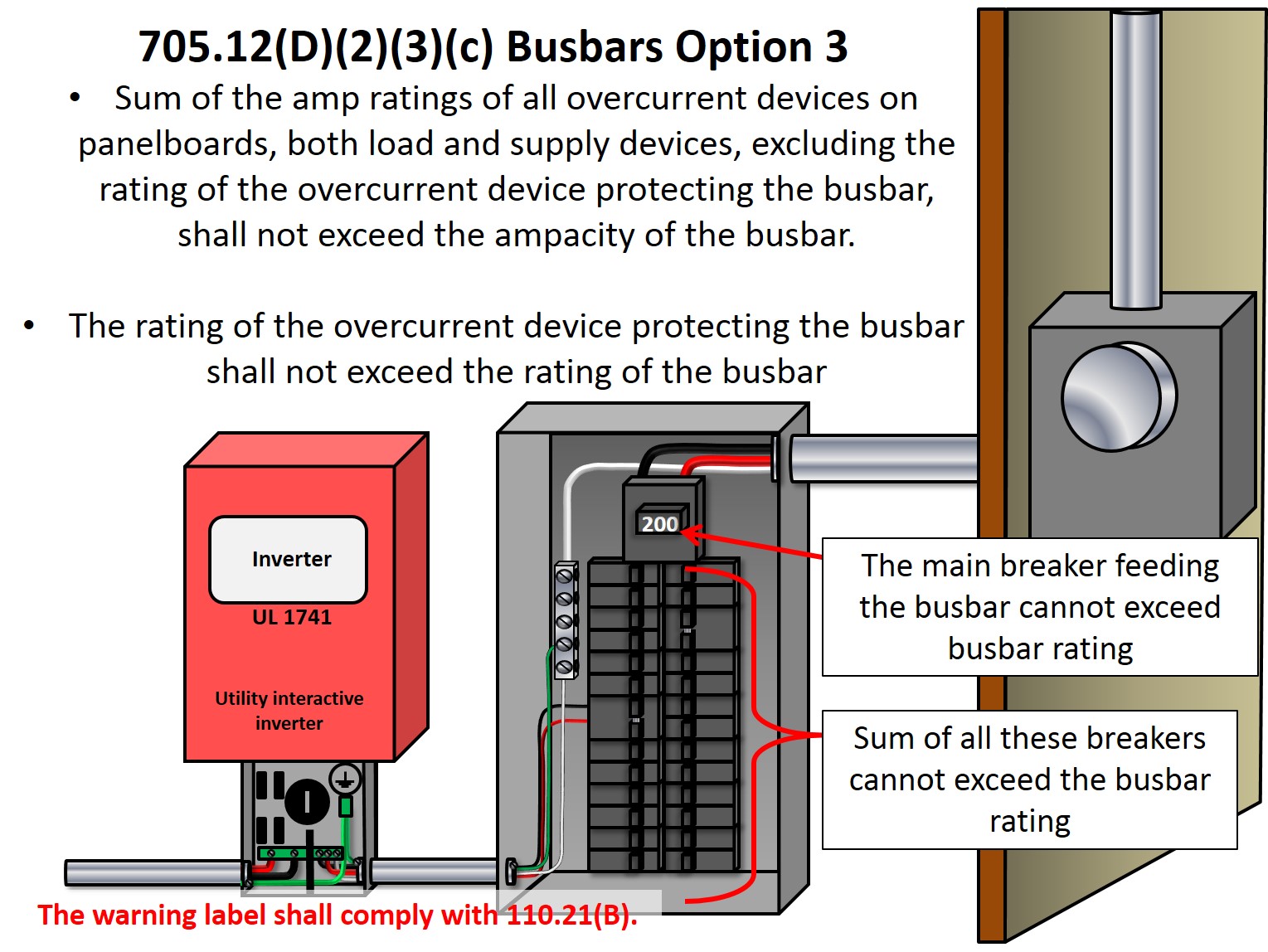

I’ll set up the scenario, but let’s first look at the calculation and define the NEC code that outlines the rule. The code section has changed over the years. When NEC 2017 went into effect in the majority of the states it switched to section 705.12(B)(2)(3), from section 705.12(D)(2) (NEC 2014), which mandates that “Where two sources, one a primary power source and the other another power source, are located at opposite ends of a busbar that contains loads, the sum of 125 percent of the power source(s) output circuit current and the rating of the overcurrent device protecting the busbar shall not exceed 120 percent of the ampacity of the busbar”. Additionally, the restrictive rule of designing under engineering supervision was removed. Now it is possible to simply install the PV breaker at either end of the panelboard without any further electrical studies. Also, there was no modification to the 120% rule with the adoption of NEC 2020. Further, it goes on to allow as much as 120% of a busbar’s rating to be exceeded. This is where the calculation comes into play.

(Busbar Rating (A) x 1.2) - Main Breaker Rating (A) = Max PV (A)

Let’s start with an example. We have a 200 Amp bus rating for our service panel. In it, we have a 200 Amp main breaker.

200A x 1.2 - 200A = 40A

In this example, the maximum output of our PV system can be 40A or approximately 9.6kW. This would satisfy the busbar rating without an issue. However, in many instances there is a need or desire to have a much larger system, so what then?

If we exceed the rating of the busbar without regard to the 120% rule, we are creating a scenario where we are feeding a panel board with too much energy and have nothing in place to prevent the sum of the loads in that panel from drawing more current than the busbar can handle. Let’s say we have a 200A service with a 200A main breaker and have installed a PV system with an output of 60A. In this case, we have exceeded the bus bar rating of the panel board and could potentially be applying 20A of excess energy to it. This could be hazardous and lead to a fire. This may sound like a no-brainer and a something that couldn’t possibly slip by inspection, but it really does happen and hopefully a lot less frequently now with knowledgeable building inspectors.

What do we do in this case? Above all else, we need to have a PV system that is safe and installed to code. What can we do to remedy this and still retain the system size we have targeted? There are a few things that can be done that do not force a load or a line side tap to be done.

The simplest solution would be to downsize the main breaker in that service panel. So in our case above we could remove the 200A main breaker and replace it with a 175A main breaker to allow us to install up to 65A of PV. Call it good, right? Well, this approach is effective when taking careful consideration of all the existing loads in that panel board. There could be a potential for these loads to draw close to or more than the ampacity of that 175A breaker. We do not want nuisance tripping, so this approach must be done carefully. Refer to NEC 220 when considering this approach.

For another possibility, assume that you determined to downsize the main breaker is not going to work. For whatever reason, the loads' calculation proved to be a complete bust. Should we pack it up and go back to the shop? Certainly not! You have another solution in your bag of tricks. Shaving!

When downsizing a main breaker is not an option for the site, you should consider amp shaving. This adds a bit more labor and costs into the mix, but it will help get that PV system stuffed into that service panel. This works well in a system that is comprised of more than one string inverter or several branch circuits of micro-inverters. The result is that you can shave off a few extra amps before you connect the sub-panel output to the main panel board.

Consider that we are using two string inverters; an SMA Sunny Boy 2500HF and an SMA Sunny Boy 5000. The output of the SB 2500HF is 10.4A requiring it to have a 15A breaker. The SB 5000 has an output of 21A requiring a 30A breaker. The sum of these breakers is 45A and we already know we cannot land them in the main panelboard because it will only allow us 40A using the 120% rule. However, if we add our PV breakers into a sub panel that is dedicated to only the PV breakers we can land the sub panel into a 40A breaker in the main panel board (10.4A + 21A = 31.4A x 1.25 = 39.25A). Voila!

In a follow-up article, I will introduce Line and Load side taps which can also be considered in installations where the PV system supplying a service would exceed that of the service rating main panel board. These are most common in commercial and light commercial installations.

Note: There is an active discussion on "Do I need a service panel upgrade?"

NEC Adoption by State: https://www.nema.org/docs/default-source/technical-document-library/nec-adoption-map.pdf

Contributions by: Thibault Dauprat

Comments

"In this example, the maximum output of our PV system can be 40A or approximately 9.6kW." Correction, inverter output is considered a continuous load (maximum current is expected to continue for 3 hours or more) per NEC 210.20(A) requires overcurrent device to be 125% of the continuous load. Therefore 32 amps would be the maximum continuous load to connect to a 40A breaker or 7.68 kW inverter output.

I am confused! If I understand correctly, currents are being summed to stay below 120% of the main breaker. But the currents from solar flow backward to the grid and therefore actual currents in the main breaker are reduced with solar, not increased.

The 120% rule is applied to the bus rating of the panel to find the maximum overcurrent protection that be added. IE it is 120% of the bus rating minus the main breaker rating to provide the amount of additional loading the solar can add. So for a typical 200A panel with a 200A main breaker there is an additional 40A that is permitted for an overcurrent protection device, which translates to 32A of continuous AC power from a solar inverter.

-Thanks again for your questions.

As long as the current consumed by the load is less than the current supplied by solar, the current feeds back to the grid. When the load becomes greater than the current provided by solar, the grid must supplement to cover the load. If the current load exceeds the sum of the main break and the solar breaker, the busbar's published current limit could be exceeded. However this is allowed up to 20% of the main breaker limit because the total current consumed by the load is not passing through the busbar from the same position since some of it is supplied by solar at the position of the solar breaker (hence opposite end of the panel recommendation). In addition, the potential total current of the load in the panel is reduced by the presence of the solar breaker which is feeding rather than loading the busbar. Theoretically if the panel is fully loaded with breakers of equal value totaling the rated limit of the main breaker/busbar, and the main breaker is at one end of the busbar, and the solar breaker is at the opposite end of the busbar, and the current provided by the main breaker and the solar breaker have the same current limit, the busbar could be loaded to 200% of its limit since only half the total current is passing through each end of the busbar. In that case, current through the busbar would never exceed its design limit at either end of the busbar. Since that can't be ensured, the 120 rule is provided.

However, if we add our PV breakers into a sub panel that is dedicated to only the PV breakers we can land the sub panel into a 40A breaker in the main panel board (10.4A + 21A = 31.4A x 1.25 = 39.25A).

During this scenario, will the individual PV breakers still remain 15A and 30A?

Correct, each inverter requires its own overcurrent protection device in the PV only combiner panel. So, 15A/2P breaker for the inverter with 10.4A output (10.4A x 1.25 = 13A) and a 30A/2P breaker for the inverter with 21A output (21A x 1.25= 26A).

Thank you for your comment and question. Let us know if you have any additional thoughts.

I don't understand this 120% rule at all, and the assumption that by adding solar, that the bus capacity must be increased, and that the load could exceed the bus rating. What does adding solar have to do with any of it? If the panelboard load is designed per NEC requirements, it will never exceed the rating of a main breaker. The loads determine how much current flows to them. If you add solar, then some flows from the solar inverter, and some from the utility power. But, never will the load demand more power than the bus is rated, unless the NEC code was violated by putting more load on the panelboard than the code allows. So, it seems to me that the only thing that makes sense is that the Code writers are making you oversize the bus, due to the assumption that some idiot is going violate the NEC and add more load to a panel than the NEC allows, just because solar is connected to the panel. So, some idiot may think that the panel is rated 200A and the solar is 40A, so I can load up the panel to 240A? That is a ridiculous assumption that someone would do that! The code doesn't allow that. So, why this ridiculous 120% rule??? If you have a 200A panelboard with an 80% rated 200A molded-case circuit breaker, then the connected load cannot exceed 160A. How does adding solar to the panel change that in any way? Solar does not add any load, it supplies power that the utility no longer provides. The sum of solar power and utility power adds up to what the load is demanding. Since there is normally a diversity of loads (since all circuit rarely run at the same time) the actual demand load is almost always less than the designed connected load. Thus, making this 120% rule even more ridiculous. Explain to me why I am wrong?

Thanks for spending the time and sharing this information.

The 125% is missing on the calculations. Art. 705.12(B)(2)(3)(b) requires that the 125% of the output circuit current to be added into the rating of the OCPD, then do the 120% rule. So using your example: 31.4x125% = 39.25A+200A = 239.25A

“But, never will the load demand more power than the bus is rated, unless the NEC code was violated by putting more load on the panelboard than the code allows.”

That’s the misunderstanding. As you point out, actual loads are way less than the breakers allow. So the NEC allows the sum of the breakers to exceed the main breaker. Run everything and you trip the breaker. If solar is feeding on the load side though, you may not trip the breaker but instead melt the bus bar.

Are there any scenarios in which the 125% rule is not applicable? i.e position of the busbar or other situations?

If we have a MSP of 200/200A and a subpanel having 200/225A rating so we can not land a 50A pv breaker in Msp but we can land in Subpanel. Is it permissible??

Hi Shahzad, thanks for your question. I'm going to just try to answer this in a general sense since I don't know what code year you need to apply. I suggest you google Mike Holt and NEC 705 before committing to any particular design!

When we're dealing with a solar circuit (or any back-fed circuit) in a panel, it's indeed considered as a source, not a load. With that in mind, let's re-evaluate:

125% of Inverter Output: This remains the same. If you're planning to add a 50A solar circuit, it is presumed that the inverter's maximum continuous output current is 40A (because 125% of 40A is 50A).

120% Rule: For back-fed sources like solar, the NEC allows for the sum of the main breaker and the solar back-fed breaker to be up to 120% of the panel's busbar rating. This accounts for the idea that the main breaker and the solar source are unlikely to be delivering their full current simultaneously. For your 225A sub-panel:

Main Breaker+(1×Solar Breaker)≤1.20×Sub-panel RatingMain Breaker+(1×Solar Breaker)≤1.20×Sub-panel Rating

200�+50�≤1.20×225�200A+50A≤1.20×225A

250�≤270�250A≤270A

This means your proposed solar setup would be compliant with the 120% rule for the sub-panel.

Remember, this rule ensures the safety of the busbars in the panel and assumes that you won't simultaneously be drawing the main panel's full load while also back-feeding the panel's full solar output.

It seems like, from a code perspective, you are in the clear to add the 50A solar circuit to your 225A sub-panel fed from a 200A main panel. However, local utility interconnection requirements, local code amendments, and other specific details of your installation might introduce other considerations. Always consult with a local electrical engineer or electrician to ensure compliance and safety. Also, if you are a contractor, Greentech can design the system for you - please contact your Greentech representative for more info!